lock Warranty Information keyboard_arrow_down

Moog fulfills their warranty through their individual dealers. That means that in order to receive warranty support, you will have to refer back to the original dealer you purchased the part from. Be sure to check the dealer's warranty support before you buy the part to make sure that they will properly support the warranty. If a dealer will only refer you back to the manufacturer in order to receive warranty support, then you may not actually have any warranty at all.

WARRANTY:

Moog Premium Steering Components carry a Limited Lifetime Warranty. Moog R-Series Control Arms, Hub Assemblies, and Strut Assemblies carry a 3 Year Warranty.

Moog warranties their parts to be free of defects in materials and/or workmanship during these timeframes as measured from the date of purchase.

If a Moog part should fail due to materials or manufacturing defect while under warranty, we will provide a replacement of the part upon return of the defective part.

Wearable RUBBER parts are not covered under warranty (Dust boots, bushings, bump stops, etc.)

Moog's u-joints are precision-ground to the strictest of tolerances, with quality-control inspection at every step in manufacturing.

Moog Universal Joints

The ultimate drivetrain addition

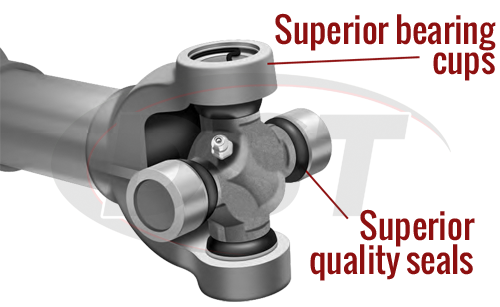

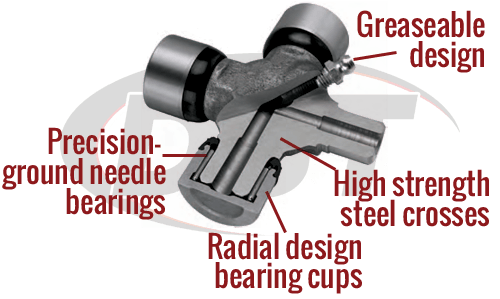

DST would like to introduce you to the ultimate drivetrain addition. Machined to meet or exceed original equipment standards, Moog premium universal joints are another addition to Moog's total undercar solutions. Moog's u-joints are precision-ground to the strictest of tolerances, with quality-control inspection at every step in manufacturing.

Problem solver technology

Moog's u-joints feature bearing cups that are cold-formed and case-hardened, providing for better strength and less wear than O.E. The superior quality seals are charged with keeping harmful road contaminants out and keeping the proper lubrication on the u-joint.

Long lasting life

These driveline components are equipped with high strength steel crosses to exceed OE specifications, and are carburized heat-treated to ensure long life. Moog includes a zerk grease fitting in the cross body for easy maintenance. The bearing cups feature a 360 degree radial design to allow even lubricant distribution to the bearing surface. Also featured are needle bearings, providing maximum load-carrying capabilities.

Lifetime warranty

Moog backs their u-joints with a lifetime warranty, which can be handled directly through our DST customer service team. If you have any other questions be sure to give us a call.

...proper installation and maintenance procedures are a must to ensure great performance and long life.

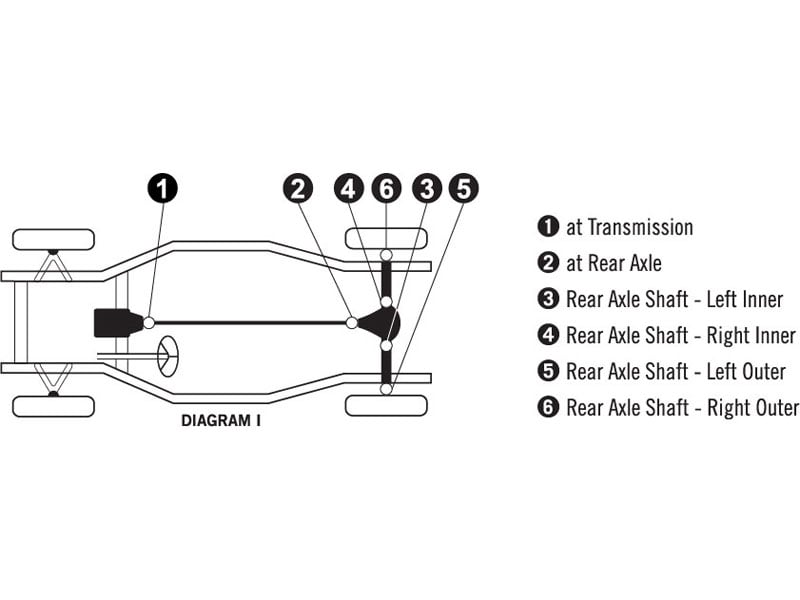

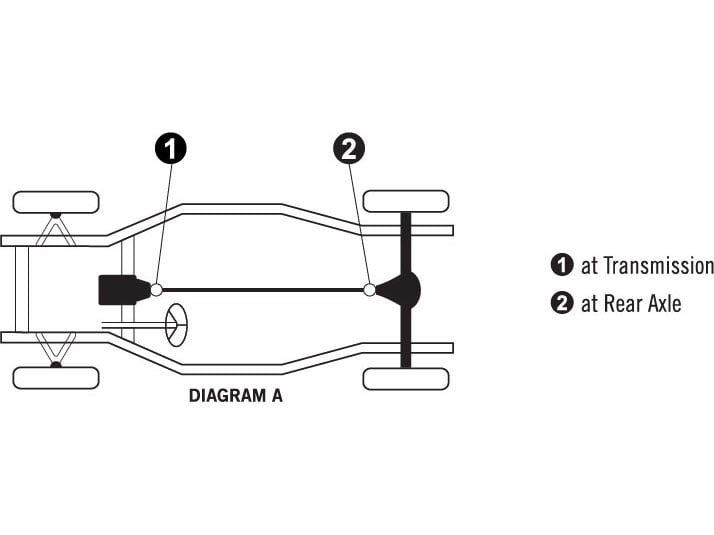

Moog U-joint Installation

Importance of proper installation

Moog Premium Universal Joints are designed with several features that enable them to meet and exceed OE standards and real world problems. That being said, proper installation and maintenance procedures are a must to ensure great performance and long life. Here are some installation tips from our DST support team to help you ensure you get the most out of your Moog U-joints.

Inspection Procedure

Moog universal joints are designed with a zerk grease fitting that fits directly into the body or in the cap.

Installation Procedure

Before you get started, it is important to note that the u-joint must be grease prior to installation. There is only enough grease in a brand new Moog u-joint to keep the needles in place during assembly. This is not a sufficient amount of grease for operation.

Before you install, there are three important steps to follow to ensure long life:

- Mark components so they can be reassembled in the same position relative to each other. This helps to keep rotational forces balanced in the drivetrain.

- Be sure to clean all mating surfaces of the yoke, especially the snap ring grooves. Doing this will allow the bear caps and snap rings to be fully seated during installation.

- Remove, lubricate and reinstall the bearing caps of the u-joint. The recommended grease for Moog premium u-joints is NLGI #2 GC-LB lithium complex EP grease, preferably a synthetic. This grease is the best for extreme pressure, high-temperature protection. Use care not to lose any needle bearings when removing and installing the cap, and make sure none of the needles are dislodged. If you are unable to find the recommend grease, make sure to use a grease that is at minimum compatible with lithium grease.

Once the u-joint is installed on the vehicle, apply grease until clean, fresh grease extrudes from all four of the cup seals. If flush type fittings are used, use a needle nozzle such as the Lincoln 5803.

Inspection Procedure

To ensure optimal performance and long life, Moog recommends greasing the u-joints at every oil change. Wipe the grease gun coupler and grease fitting down before you attempt to push in new grease, making sure the bearing is not contaminated by dirt. Just as during installation, slowly add grease until clean, fresh grease extrudes from all four cup seals. Not only does this allow fresh lubricant to reach critical areas, but it ensures that new grease is spread evenly across all bearing surfaces and eliminates any debris.

Also while servicing your u-joints, inspect the seals for any damage. Be sure to clean away excess grease away from the seals and grease fittings after you service them. If the vehicle is used in more demanding road conditions, like racing, off-road or high-impact vehicles, more frequent service is required. Any u-joints that have been submerged in water need to be re-lubricated as soon as possible to prevent rust or corrosion from forming. Any questions you have don't hesitate to ask our DST Customer Service team!